Screening For Wind Trouble at Auckland International Airport

The Auckland International Airport Transport Hub is arguably the busiest in the country. With over 10,000 vehicle movements per day and tens of thousands of passengers walking past, any issues of noise from the perforated facade would create a significant and embarrassing problem for our gateway to the world.

The Situation

The biggest change to Auckland’s international terminal transport system for almost 50 years would revolutionise the arrival and departure experience for over 18 million passengers per year, making the new Transport Hub the busiest under-cover transit facility in New Zealand. Every 5 seconds a vehicle could enter the pick-up/drop-off lanes and soon after opening, 10,000 vehicles movements a day would be recorded, helping move up to 50,000 passengers.

Located next to the International Terminal, adjacent to gateway hotels and providing a sheltered walkway to the domestic terminal, the Transport Terminal is a high throughput facility in a high wind zone. The wind comes predominantly from the South-West, which is why planes almost exclusively take-off and land from the North-East.

The Hub uses over 8500m² of perforated screening. The potential for wind-induced noise and vortex-induced oscillation posed a risk which could play out under the gaze (and within earshot) of enough connected travellers to pose a significant problem for the Airport, making wind-tunnel testing critical.

Testing Methodology

Auckland Airport records an average of 55 days per year with gusts exceeding 55 km/hr, with 3 days exceeding 96 km/hr. The highest speed ever recorded was 147 km/hr on 6th September 1981.

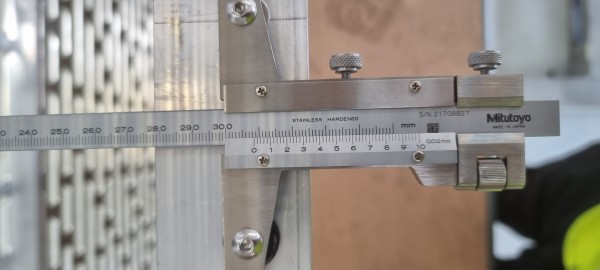

Testing the initial perforated pattern found noise generation to unacceptable levels at 15 m/s (or 54 km/h) with a very unpleasant pitch recorded. With tolerance for wind-induced noise set to zero, the testing followed an iterative process whereby each pattern created was altered until no noise was recorded.

A Performance Mock-Up (PMU) was then used to test the proposed final assembly, analysing the expected deflections to see if wind-induced vibration was likely to cause issues over time, and to check the deflections would not be liable to cause any alarm or visual discomfort for the tens of thousands of passing travelers. Accompanying this was a full scale Visual Mock-Up (VMU) enabling both the Architects and the Client to critically review how the finished facade would look.

Testing Results & Recommendations

The initial perforated pattern specified performed poorly in both acoustics and deflections. By testing subsequent patterns using an interactive process, we were able to modify the pattern to a point whereby it would produce no noise while maintaining the architectural intent.

Multiple variations of the pattern were needed to reach that point, each being subjected to increasing wind speeds at different angles, the 1:1 mock-up being rotated by 15 degrees on the turntable between each test.

The client was able to view the panel under full wind load and understand how it would look and perform in the eyes of concerned travelers passing by.

Conclusion

By incrementally changing the pattern we were able to preserve the original vision for the Transport Hub. No noise was generated by the adapted pattern even in wind speeds exceeding the daily average at the Airport, or at an expected (and unexpected) gust level.

Furthermore, we were able to prove the fixings would be able to hold fast against vibrations and expected wind loadings, maintaining the structural integrity of the facade.